Why Retransfer ID Card Printing Delivers Superior Quality and ROI

Direct-to-card (DTC) printing provides what experts call “edge-to-edge” coverage, meaning the text can be printed just up to the edge of the card — but because there’s a slight margin between the card’s edge and the print ribbon, finished cards usually have a slight blank white border. This seemingly minor detail can significantly impact the professional appearance of employee ID cards, visitor badges, and access cards, and signal to clients or employees that corners were cut, literally and figuratively.

In contrast, over-the-edge printing via retransfer technology solves the white border problem, resulting in a more professional-looking badge that’s also scratch-resistant, fade-resistant and durable.

In this post, we’ll take a closer look at the retransfer process and how to tell if it's a good fit for your organization.

Challenges of DTC Badge Printing

There’s nothing wrong with having a slim border around your cards. In fact, for many, DTC printing is an affordable and efficient way to produce ID cards. But there are a few challenges that come with DTC badge printing, including:

Quality perception. When employees, clients or visitors see a badge with a visible white edge, it can unconsciously signal lower quality and a lack of attention to detail. Even if users cannot articulate exactly why a badge looks unprofessional or cheap, the lack of polish and intentionality comes through.

Durability. Beyond the visual, DTC printing can be less durable in the long term. They are more susceptible to scratching and fading over time, particularly in high-use environments where cards are frequently handled, swiped through readers or stored in wallets.

Surface compatibility. Modern access control cards often feature embedded RFID chips, magnetic stripes or smart card components that create uneven surfaces. When DTC printers attempt to print on these textured surfaces, the printhead comes into direct contact with the card, potentially causing print quality issues, equipment wear or even damage to the card's embedded components.

What Is Retransfer Printing?

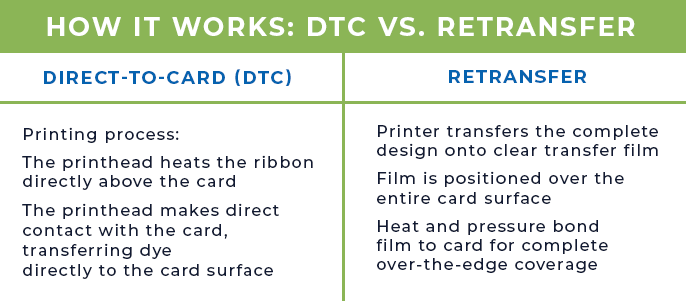

Because retransfer printers do not print directly onto the card surface, the image can extend slightly over the edge, allowing it to fill the entire surface. Here’s how it works:

The card image is sent to a specialty printer like the Smart 81 from IDP or the ZXP Series 9 from Zebra. These retransfer ID card printers print onto an overlay film included in the ribbon. The film is then adhered to the card’s surface using both pressure and heat, creating what's known as over-the-edge ID printing.

This all-in-one process offers significant advantages over direct printing methods.

- The film-to-card transfer mechanism ensures consistent print quality regardless of surface variations.

- The film overlay offers superior adhesion and durability compared to direct printing methods.

- The overlay also provides additional protection for the printed image, enhancing durability and scratch resistance.

The over-the-edge advantage is immediately visible in the finished product. Over-the-edge printing creates a professional appearance that extends the design completely to the card's edges, matching the quality expectations of modern branded materials.

A Closer Look: Retransfer Printers

Modern retransfer printers like the IDP Smart 81 and Zebra ZXP Series 9 offer high-resolution ID card printing capabilities that deliver professional results for demanding applications. These enterprise-level solutions provide the reliability needed for high-volume card production while maintaining consistent quality standards.

Making the Business Case for Retransfer

The benefits of retransfer printing extend beyond the initial equipment investment, creating value through multiple channels that impact both immediate operations and long-term costs.

- First impressions count. Visitors and clients form impressions based on these visible indicators of organizational professionalism. When employees carry professionally printed ID cards, it reflects positively on a company's attention to detail and quality standards.

- Engagement matters. Employee pride and engagement can also benefit from high-quality ID cards. When staff members receive cards that look professionally produced rather than homemade, it reinforces their connection to a quality organization. This psychological impact, while difficult to quantify, contributes to overall workplace satisfaction and professional identity.

- Savings over time. While retransfer printers typically cost more upfront than direct-to-card alternatives, they offer higher print quality and versatility in terms of the card surfaces they can handle. This versatility reduces the need for multiple printing solutions when working with different card types. Reduced replacement needs represent a significant ongoing cost advantage.

- Quality that lasts. The superior durability of retransfer-printed cards means they maintain their appearance longer, reducing the frequency of card replacement due to wear, fading or damage. For large organizations, this reduction in replacement volume can generate substantial savings over time.

- Time and equipment savings. Lower maintenance and support costs also contribute to the total cost of ownership advantage. Because retransfer printers don't require direct contact between the printhead and card surface, they experience less wear on critical components, potentially reducing maintenance requirements and extending equipment life.

Who Needs Retransfer Printing?

The decision to invest in a retransfer printer comes down to a few key considerations:

- Volume. If your company is printing hundreds or thousands of cards annually, retransfer can improve durability and reduce replacement costs over time.

- Visibility. For organizations that need to portray a professional and polished image, edge-to-edge printing allows for consistent brand presentation without distracting white borders.

- Security. For cards with uneven surfaces like RFID and Prox cards, retransfer offers a better printing experience without sacrificing functionality or damaging embedded components.

Investing in Professional Quality

The choice between DTC and retransfer printing ultimately comes down to quality standards and long-term value. Organizations that view ID cards as extensions of their brand and professional image find that retransfer printing's superior quality justifies the additional investment.

Professional appearance isn't just about looking good, it's about projecting the attention to detail and quality standards that define successful organizations. When every interaction, from employee badges to visitor cards, reflects professional quality, it reinforces the organization's commitment to excellence in all areas of operation.